In this blog series, dr. Wesley De Boever, micro-CT product marketing manager at TESCAN introduces the fundamental principles of micro-CT. And there is no better topic to kick off this blog series than spatial resolution.

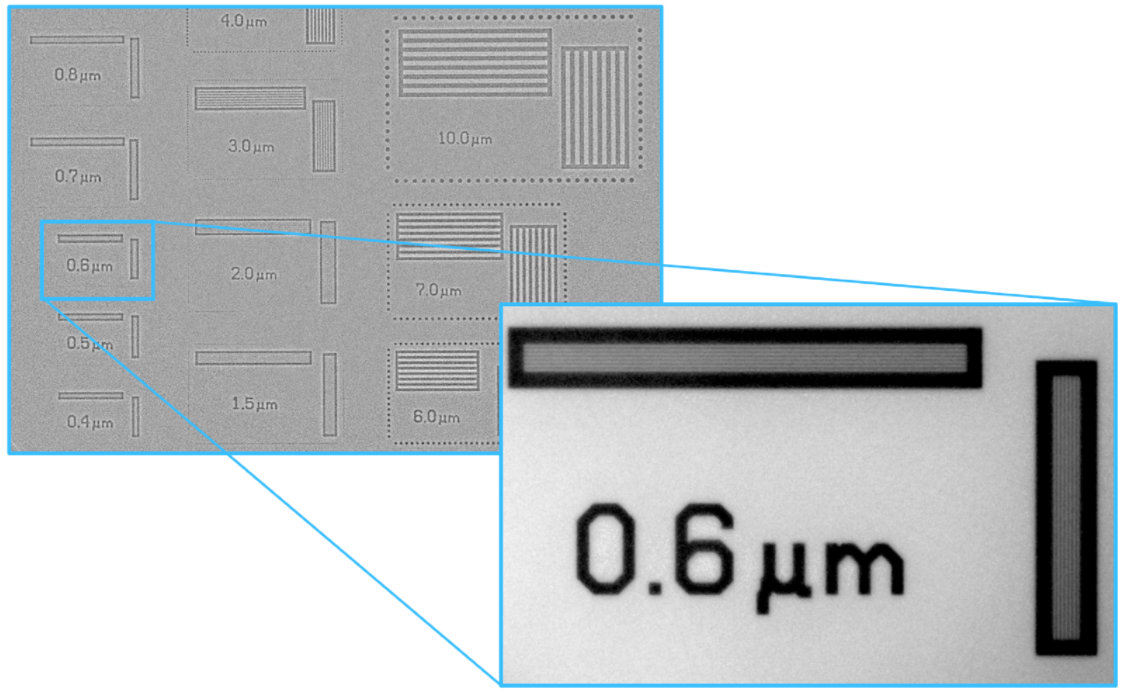

Spatial resolution refers to the resolving power of a micro-CT system. Typically, it is measured on a 2D resolution pattern, such as a JIMA pattern or Siemens star, where line pairs with a known distance between them are resolved with sufficient clarity to determine the maximum resolution under ideal conditions.

This method depends on the spot size of the x-ray source used. This spot size is the resolution limit for systems that rely on geometric magnification, as well as on the target thickness of the x-ray source, focusing mode, or power of the source.

-- See Latest MicroCT Products from Tescan --

Currently, most high-resolution micro-CT systems, in their optimal imaging conditions, can resolve features that are spaced between 0.5 and 0.9 µm from each other, as can be seen in the figure below.

Figure 1: (left) Low-resolution radiograph of the JIMA resolution pattern acquired with TESCAN UniTOM HR; (right) High resolution radiograph where 600 nm spaced line pairs are clearly resolved.

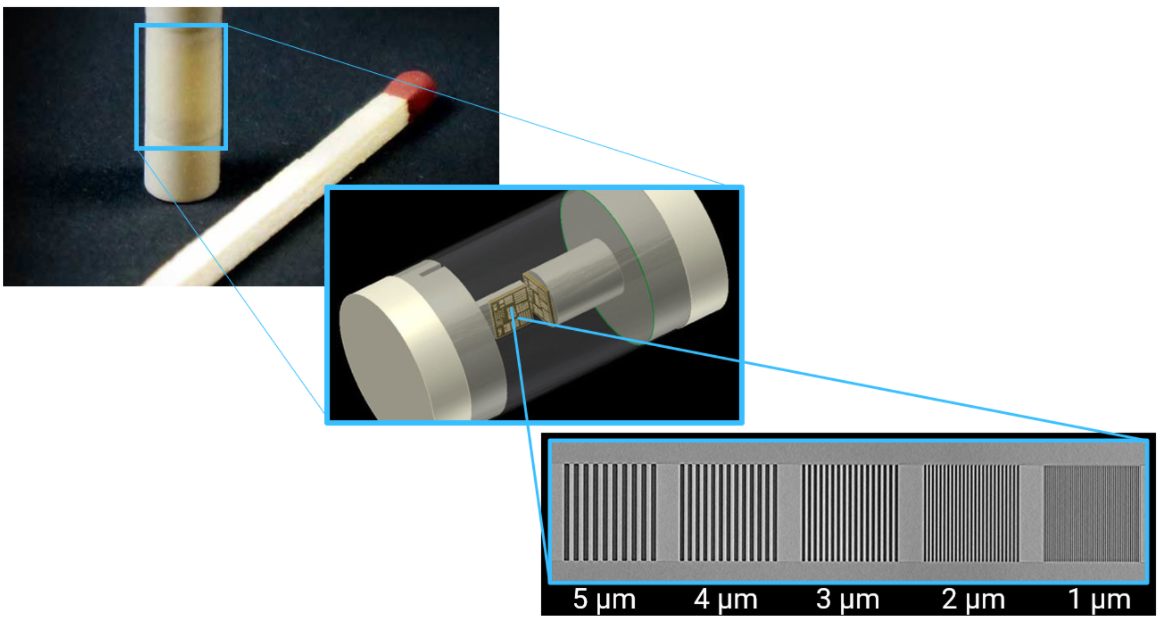

Measurement of 3D spatial resolution needs to be performed on a 3D resolution phantom, such as a QRM bar phantom. In this case, 2D radiographs need to be acquired over a 360° rotation, followed by a reconstruction into a 3D volume.

Since a full scan is needed to analyze such a 3D resolution phantom, all components of the CT scanner (rotation accuracy, vibrations, source stability, etc.) are taken into account and the true resolution of a micro-CT system can be evaluated.

Figure 2: (left) Photo of QRM nano bar phantom; (middle) computer render of the inside of the QRM nano bar phantom,

and (right) actual reconstructed slice of the QRM nano bar phantom using the TESCAN UniTOM HR.

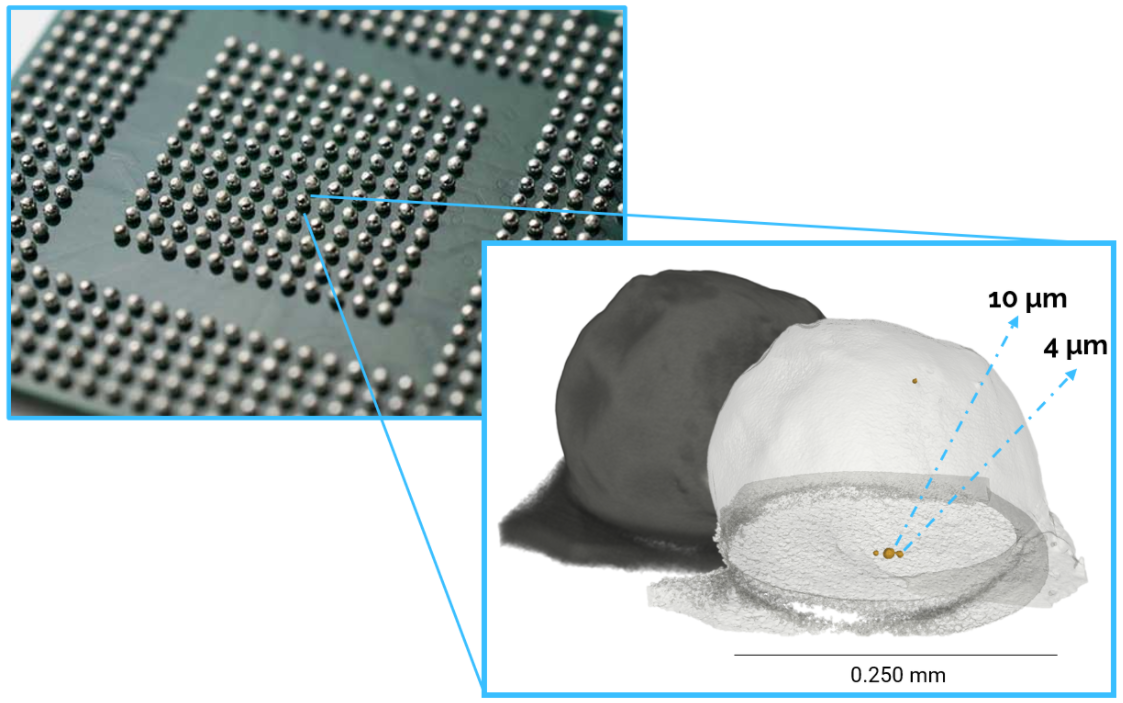

Of course, the benefit of high spatial resolution is severely diminished when it takes many hours — even days — to acquire datasets. JIMA and QRM phantoms are made from low-attenuating materials and are measured under ideal imaging conditions, without a time limit. The TESCAN micro-CT systems aim to preserve high spatial resolution at challenging conditions, such as during fast and high-throughput acquisitions or during in-situ experiments. Maintaining resolution during short scans (< 1 hour) allows many more users to take advantage of the micro-CT system.

In day-to-day terminology, the resolution is often synonymous with voxel size. A voxel is the equivalent of a pixel in a 3D volume, and if the dimensions of a voxel are larger than the used focal spot size of the x-ray source, the voxel size is indeed the resolution limit of a 3D dataset. TESCAN micro-CT systems automatically maximize source power (x-ray flux) for a given voxel size, to get maximum speed without sacrificing image resolution.

In the next blog post of this series, we will discuss temporal resolution.

Figure 3: High-resolution scan of a solder ball from a ball grid array with size analysis of defects. 650 nm voxel size was

achieved in 50 minutes scan time.

If you have questions about the Micro-CT portfolio, please do not hesitate to contact your local TESCAN representative!

Wesley De Boever

Product marketing Manager for TESCAN micro-CT